CO2 FLAME POLISHING

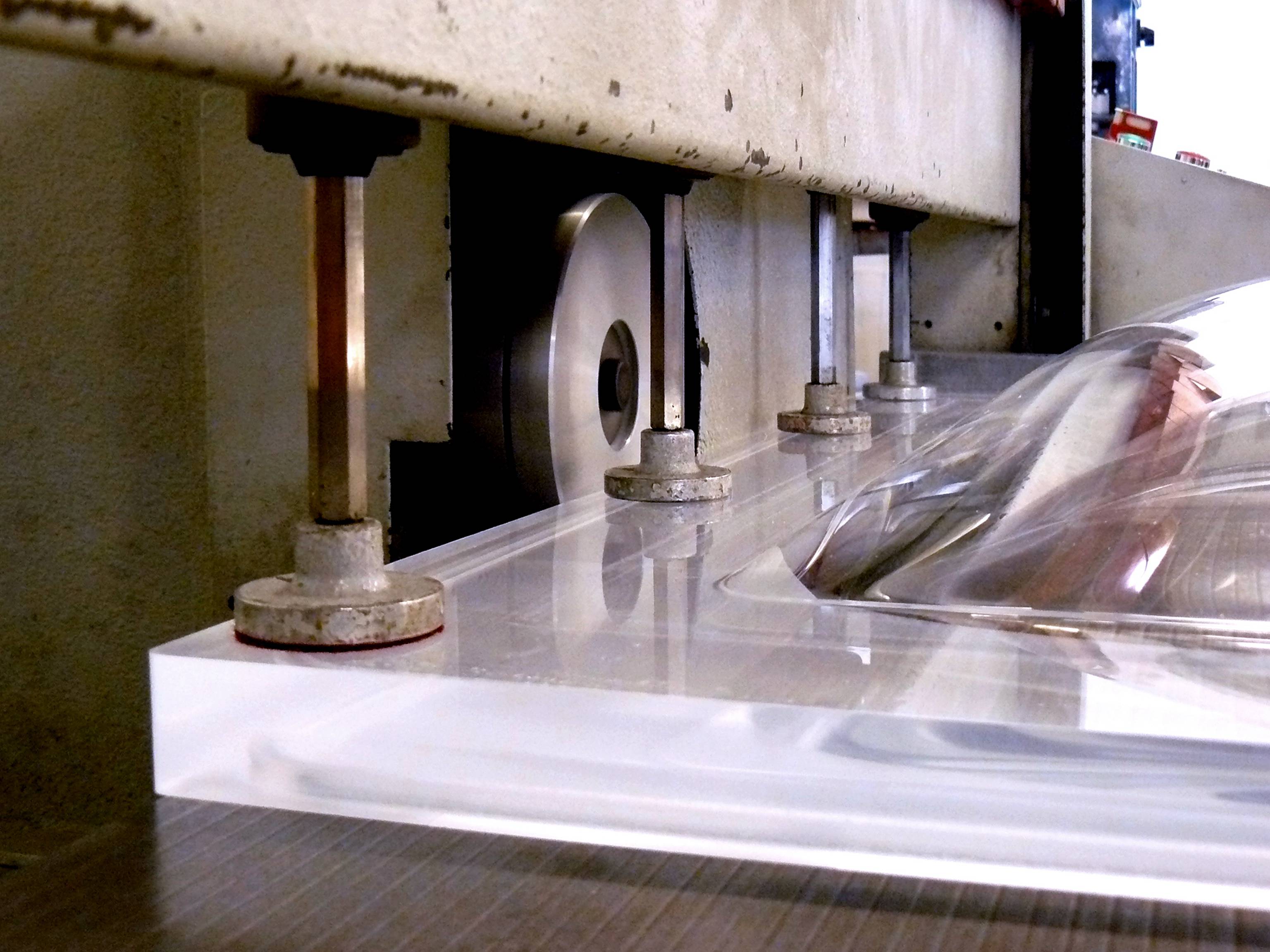

The POLISHING OF METHACRYLATE is obtained by heating with CO2 flame methacrylate edges or parts remained in the raw state after cutting operations through numerical control machining centers CNC, giving transparency and brilliance of high quality.

EN

EN IT

IT DE

DE FR

FR